Structures

Complexity made simple!

Reduced weight, increased safety: What once might have been a contradiction in terms is today’s norm. The conflicting demands on the structural components that make up today’s vehicles are complex. And with the drive towards greater sustainability, they are on the increase. We are pioneers in the field of steel, aluminum and multi-material lightweight construction. We support the integration during the concept phase using all standard CAD and CAE systems and optimize product weight and performance. We develop global platforms and take care of industrialization and production close to our customers. Our robust and state-of-the-art manufacturing processes allow us to ensure the highest standards of quality

From material development to component design and simulation to series production of components and modules, we offer you a full service, tailored to your needs. All focused on lightweight construction and cost-efficiency.

From front to rear end: Our vehicle structures

Our product portfolio includes structural components and assemblies for body in white, crash management systems, cockpit crossmembers, and carrier systems for energy accumulators in electrically powered vehicles.

Series ready

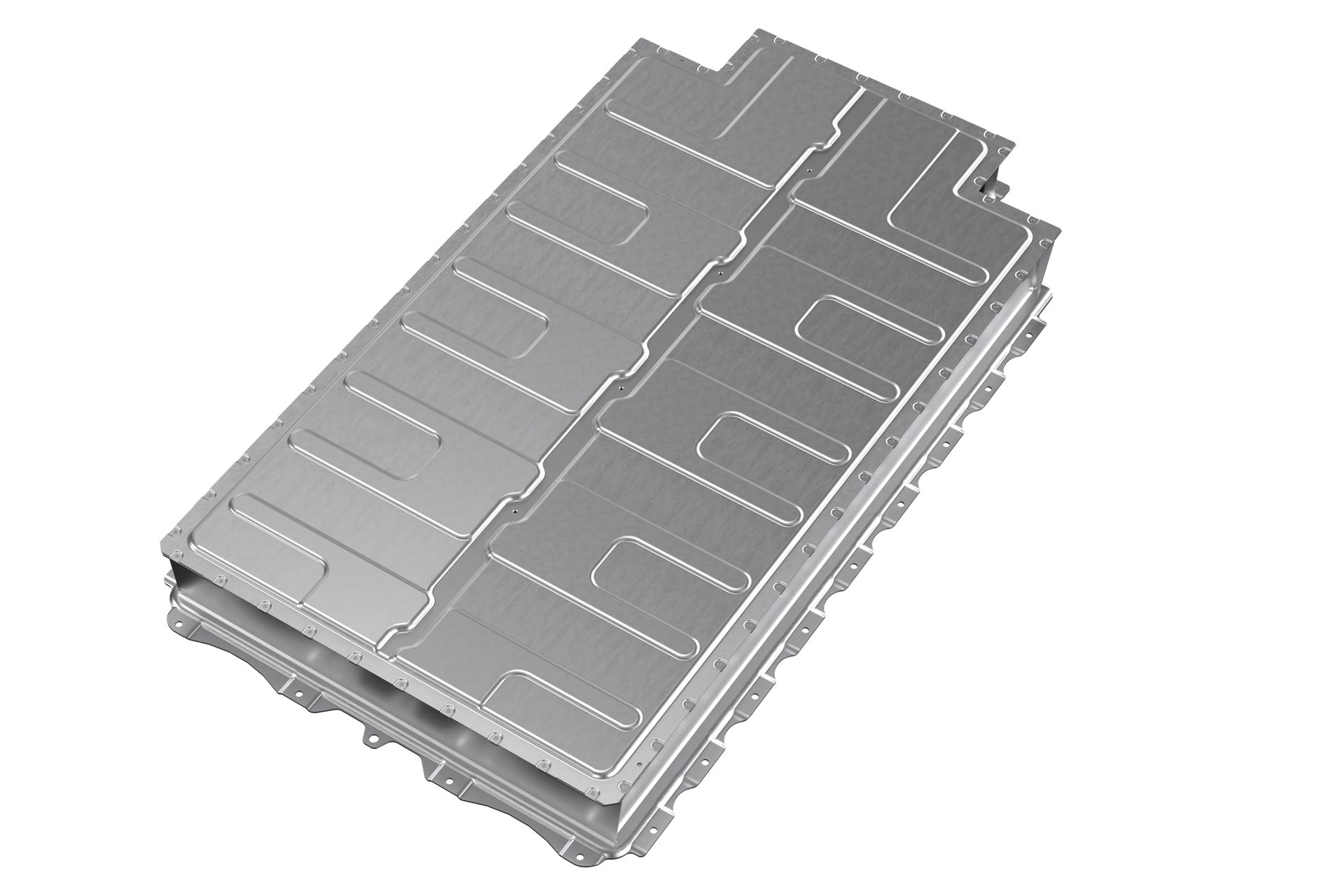

Our battery storage systems

Good to know that we are also a leading tier-one supplier of battery storage systems for electric vehicles. We are with several models already in serial production. We cover all relevant customer and legal requirements for rechargeable energy storage systems.

Aluminum, steel or multi-material design – the choice is yours. With aluminum solutions, profiles made of 6xxx alloys are preferred. The reason? Weight reduction, safety, tightness and modularity. Additionally, we offer advanced and highly integrated cooling solutions, providing additional weight reduction compared to external cooling.

Economical

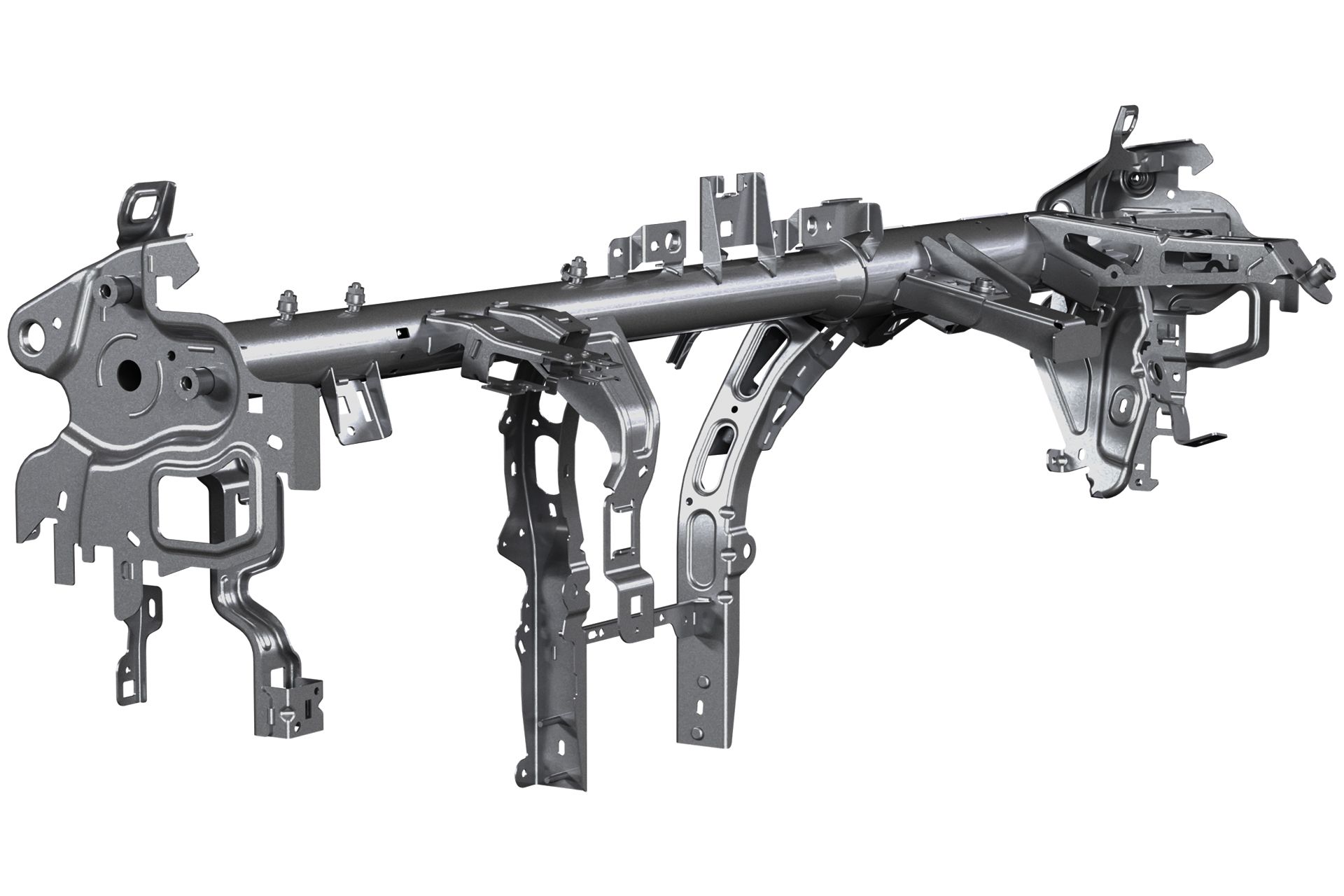

Our structural components

From a single steel or aluminium component to a complex multi-material assembly – the added value for our customers is clear: Less weight, greater crash safety and sustainable emission reduction. We develop load-condition-optimised designs for large-scale production by optimizing thickness and strength. Both in conventional and highly innovative production processes.

With aluminum, we push the limits of weight reduction with tailored extruded blanks and profiles and remain economical. We create body components from high-strength alloys through complex forming and component integration. For multi-material solutions, we combine our expertise in development and large-scale production.

Light

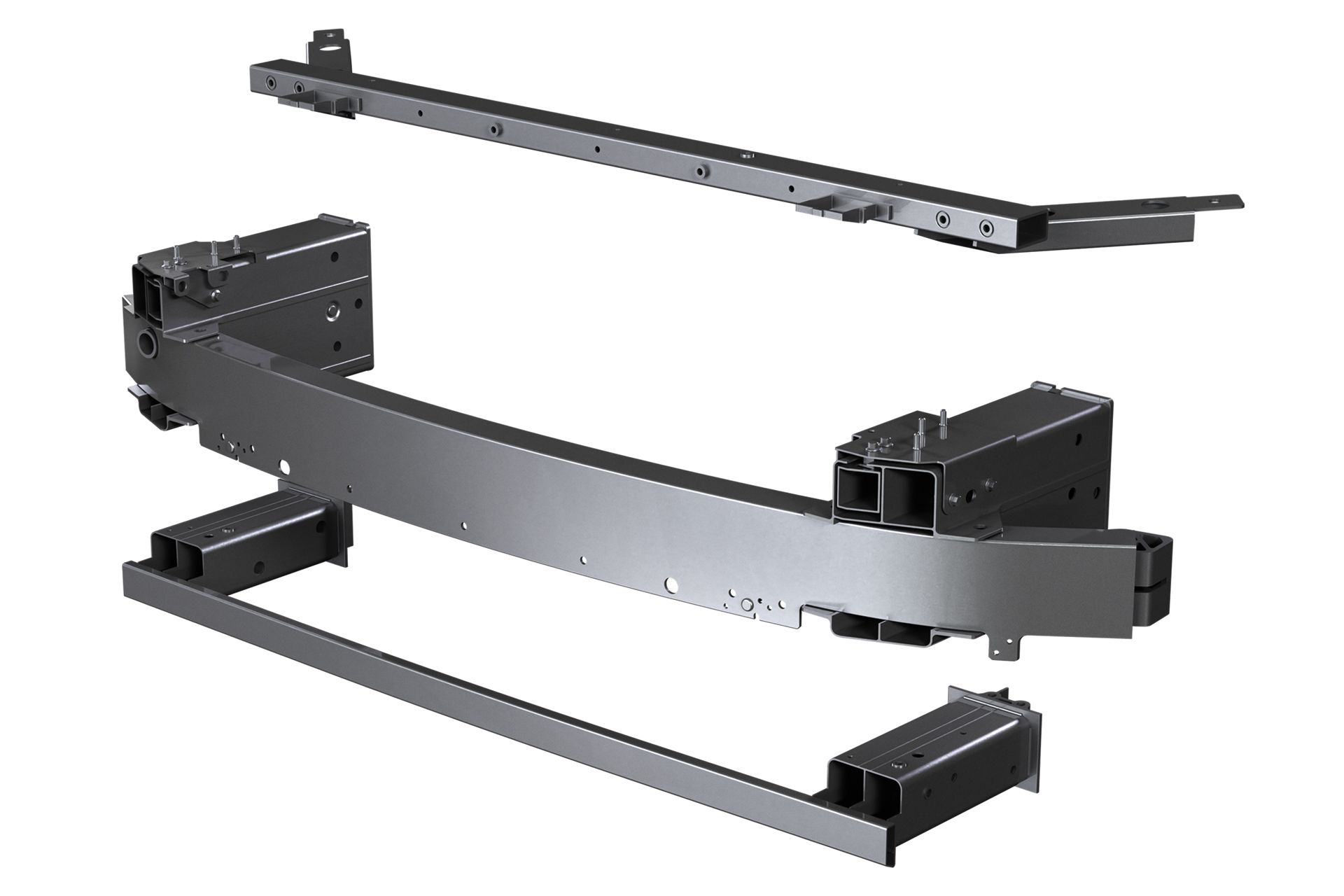

Our crash management systems

Our crash management systems are designed for optimal crash performance and low weight. Systems can be designed in steel, aluminum or multi-material, depending on your specific requirements.

With our extensive expertise in aluminum and application-specific alloys, our lightweight solutions offer weight reductions of up to 40 % over steel. Our multi-material solutions combine our competence in development and high volume production for steel and aluminum.

Innovative

Our instrument panel supports

We develop and produce instrument panel supports for many OEMs around the world. Our portfolio includes innovative lightweight solutions made of steel and aluminum.

Our instrument panel supports are joined while integrating multimaterial elements using screw, plug-type or welding connections. Our in-house tube and press part production together with a wide supplier network ensures cost-efficient component supply.