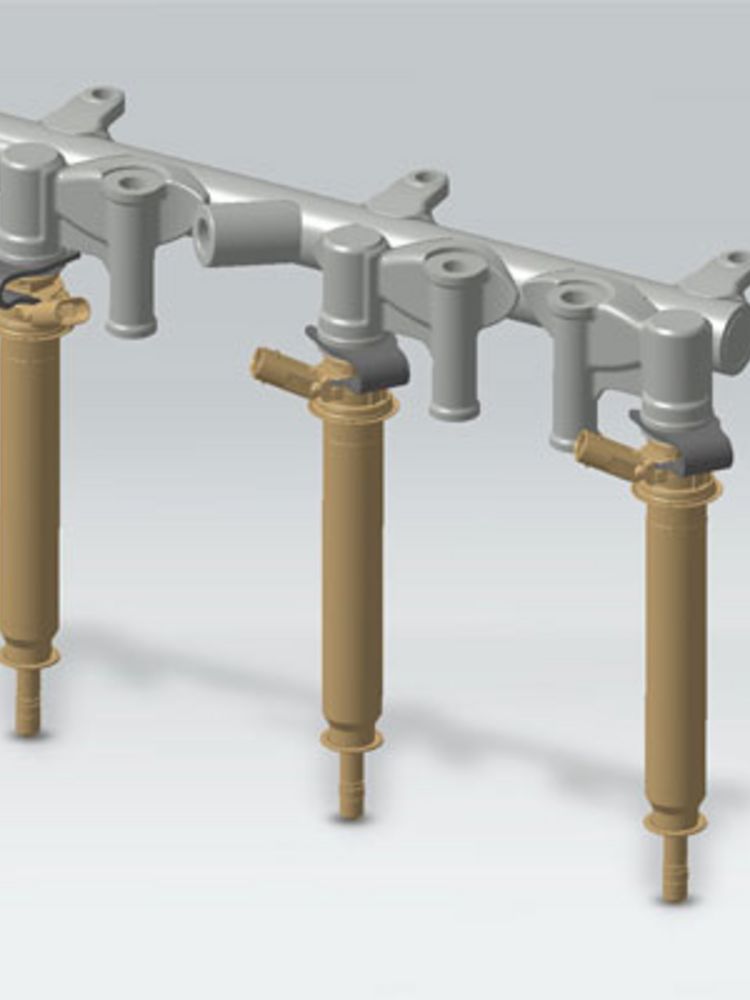

BENTELER makes injector assembly cost-effective, fast and reliable

Salzburg/Paderborn, September 02, 2020. The assembly of injection nozzles is complex. BENTELER relieves car manufacturers of the delicate work. With fully automated injector assembly in an own clean room. Injection nozzles - or injectors - ensure that the gasoline is atomized in an engine in exactly the right amount and at exactly the right time. The sensitive parts can easily be damaged during assembly. It is also important to avoid contamination during assembly. At BENTELER, this is therefore carried out in a so-called clean room - fully automatically, precisely and camera monitored.

One concept for all injector variants

BENTELER masters fully automatic injector assembly for all injector variants: from highly sensitive piezo injectors, which require even more care during assembly, to magnetic injectors for gasoline or petrol engines and injectors for water injection.

Comprehensive vehicle know-how, that takes work off car manufacturers

Several test steps ensure correct execution and also save time for the car manufacturers. They do not have to carry out these tests themselves: whether simple functional tests on the high-pressure sensor or leakage tests in the module, BENTELER takes care of the tests. In addition, BENTELER has a lot of experience in the development and production of fuel rails. The complete injector assembly is therefore perfectly matched to the fuel rails. Sensors and cameras monitor the work steps at several locations. Thus, errors are immediately detected and avoided - such as damaged or missing seals.

"So far, we have been carrying out fully automatic injector assembly in Western Europe. Our goal is to offer this service worldwide," says Eugen Aul, Director Business Development at BENTELER in Paderborn: "This gives our customers maximum flexibility.”